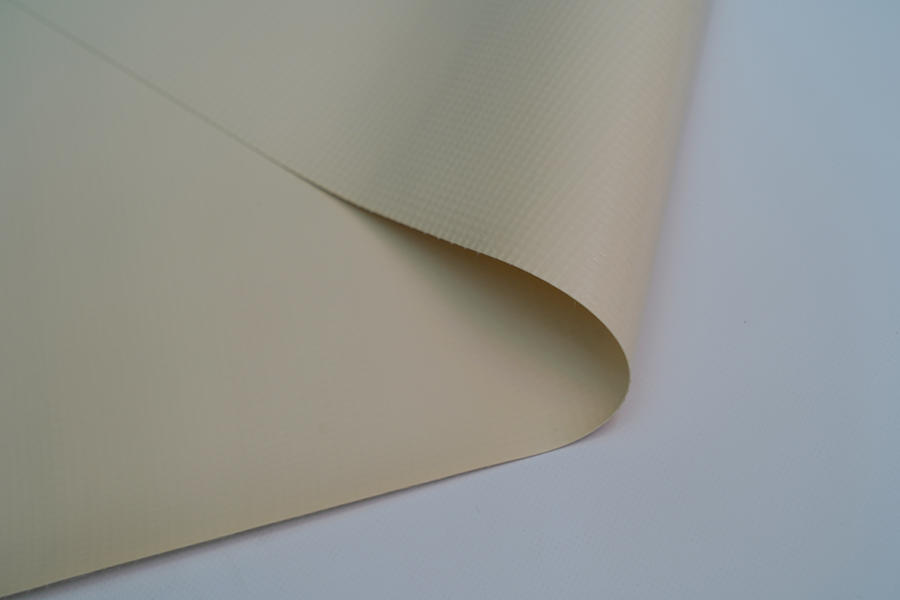

The lifespan of a PVC (Polyvinyl Chloride) architectural membrane can vary depending on several factors, including the quality of the material, the environmental conditions it is exposed to, and how well it is maintained. However, under proper conditions, PVC architectural membranes are known for their durability and long service life. Here are some general guidelines regarding the lifespan of PVC architectural membrane:

Quality of Material: The quality of the PVC membrane material plays a significant role in determining its lifespan. High-quality PVC membranes, often referred to as "top-tier" or "premium" membranes, are designed to last longer and resist environmental factors better

than lower-quality options.

Environmental Conditions: The environmental conditions to which the PVC membrane is exposed can have a significant impact on its lifespan. Factors such as UV radiation, temperature fluctuations, pollution, and exposure to chemicals can affect the membrane's longevity.

Membranes in harsher environments may have a shorter lifespan.

Proper Installation: Correct installation is crucial for the longevity of PVC architectural membranes. Improper installation, including issues like inadequate seam welding or insufficient fastening, can lead to premature membrane failure.

Maintenance: Regular maintenance can extend the lifespan of PVC membranes. This includes cleaning to remove dirt, debris, and pollutants that can degrade the material over time.

Proper maintenance can also help identify and address small issues before they become significant problems.UV Resistance: Many PVC membranes are formulated with UV stabilizers to resist the damaging

effects of prolonged sun exposure. The UV resistance of the membrane can influence its lifespan, with UV-resistant membranes lasting longer in sunny climates.

Climate: Climate conditions, such as temperature extremes, humidity levels, and the frequency of freeze-thaw cycles, can impact the lifespan of PVC membranes. Membranes in regions with extreme climates may experience more significant wear and tear.

Use and Traffic: The level of foot traffic or other activities on the membrane can affect its wear and tear. Membranes in high-traffic areas or those subjected to heavy loads may have a shorter lifespan.

Generally, PVC architectural membranes, when well-maintained and installed correctly, can have a service life ranging from 20 to 30 years or even longer. Some premium PVC membranes come with warranties that guarantee their performance and longevity within specified conditions.

It's essential to consult with manufacturers or experts in the field when selecting a PVC membrane for a specific project to ensure it meets the required standards and is suitable for the intended use and environmental conditions. Regular inspections, maintenance, and adherence to manufacturer-recommended guidelines are also crucial for maximizing the lifespan of PVC architectural membranes.

English

English 简体中文

简体中文 عربي

عربي