Selecting the right industrial fabric often feels like navigating a maze. Each application demands specific traits—marine environments need waterproofing, aerospace requires heat resistance, and construction relies on tear strength. While many fabrics excel in one area, PVC fabrics stand apart by combining critical properties into a single solution.

PVC (polyvinyl chloride) fabrics are engineered synthetic textiles designed to thrive in extreme conditions. From heavy-duty truck tarps and firefighter gear to lightweight inflatables and architectural canopies, PVC’s adaptability bridges gaps between performance and practicality, outperforming traditional materials like leather, rubber, and untreated fabrics.

Why PVC Fabrics Outperform Competitors

PVC fabrics dominate industrial use due to their energy-efficient production, ease of customization, and exceptional longevity. Unlike natural fibers or metals, PVC inherently resists water, chemicals, and UV degradation. Its synthetic structure allows manufacturers to fine-tune flexibility, flame resistance, and texture without sacrificing core durability. These traits make PVC a cost-effective choice for high-stress environments, from construction sites to military operations.

Key Qualities of PVC Fabrics

The versatility of PVC fabrics stems from their unique physical and chemical properties:

Unmatched Durability

Resistant to abrasion, tearing, and punctures, PVC withstands harsh conditions like saltwater exposure and temperature extremes (-30°C to +70°C).

100% Waterproof

PVC’s non-porous structure blocks water penetration, ideal for marine covers, inflatable boats, and outdoor shelters.

Chemical & Oil Resistance

Withstands acids, alkalis, oils, and solvents, making it essential for chemical liners, lab aprons, and industrial wipes.

UV Stability

Retains color and strength for years under sunlight, critical for awnings, signage, and outdoor furniture.

Flame Retardancy

Halogens (chlorine, fluorine) in PVC inhibit combustion, meeting safety standards for theater curtains and protective gear.

Low Maintenance

Resists mold, stains, and microbes; easily cleaned with soap and water, reducing lifecycle costs in healthcare and hospitality.

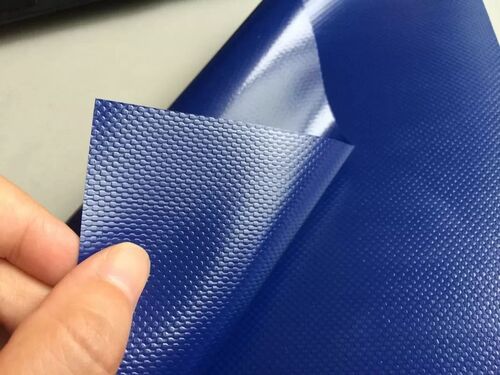

Design Flexibility

Available in textures (smooth, embossed) and colors (transparent, metallic), enabling branding and functional designs.

Common Uses of PVC Fabrics

From everyday items to specialized equipment, PVC’s adaptability fuels its presence in:

-

Transportation

Truck tarps, boat covers, and aircraft liners leverage weatherproofing and tear resistance. -

Construction

Temporary shelters, tensile roofs, and erosion-control geotextiles rely on strength-to-weight ratios. -

Safety Gear

Firefighter suits and chemical aprons integrate PVC for flame and toxin resistance. -

Consumer Goods

Inflatable pools, gym mats, and waterproof backpacks prioritize durability and safety. -

Advertising

Billboards and banners use PVC for vibrant, weather-resistant graphics. -

Agriculture

Greenhouse covers and livestock curtains benefit from UV stability and microbial resistance.

The Science Behind PVC’s Versatility

PVC’s amorphous molecular structure and polar chlorine atoms enable seamless blending with additives like plasticizers and stabilizers.

This allows engineers to adjust:

-

Elasticity for medical tubing

-

Fire Resistance via antimony trioxide

-

Antimicrobial Protection with silver-ion coatings

-

Recyclability through phthalate-free formulas

Unlike rigid plastics, PVC fabrics can be reprocessed multiple times, aligning with circular economy goals.

Conclusion

PVC fabrics are reshaping industries by replacing wood, metal, and traditional textiles in applications demanding lightweight resilience. Their ability to resist water, chemicals, and environmental stress—while remaining cost-effective—explains their ubiquity in industrial and consumer markets.

As sustainability drives innovation, PVC’s recyclability and energy-efficient production cement its role as a future-proof solution. For a deeper dive into optimizing PVC for your projects, please feel free to contact us!